🎙️ DIY Gun Coating Guide with the BRN-180: Alumahyde vs. Cerakote – Reliability, Technique & Results

In this episode, the host dives deep into his DIY rebuild of the BRN-180 rifle, a short-stroke piston AR-180 variant by Brownells and Primary Weapons Systems. With over 7,000 rounds and remarkable reliability, the BRN-180 earned a full refresh featuring a Geissele SSP single-stage trigger for fast resets, ideal for steel target shooting out to 300 yards.

The core of the episode explores DIY gun painting, focusing on Brownells Alumahyde spray epoxy as a durable alternative to professional Cerakote jobs. The host shares:

Step-by-step prep and application tips: disassembly, degreasing, surface drying, and proper hanging techniques.

Best Alumahyde colors (Parkerized Gray, Silver, Black, FDE) and layering with rattle cans for camo.

Application secrets: sponge techniques, using blowout nozzles, and oven-curing at 150°F for fast, hard finishes.

Pros & cons of DIY finishes and how Alumahyde compares to Cerakote and appliance epoxies in durability.

This episode is packed with practical tips, from avoiding clogs to choosing the right colors and maximizing paint adhesion on anodized aluminum. The host wraps up with a poetic tribute to the BRN-180 in a touching audio segment titled “Bufferless Lover.”

🎯 Perfect for AR builders, DIY gun enthusiasts, and anyone curious about firearm customization on a budget.

BRN-180 Rebuild: DIY Brownells Alumahyde Sponge Camo That Looks Like Cerakote

Meta description: A BRN-180 short-stroke piston rebuild gets a Geissele SSP trigger and a rugged Brownells Alumahyde DIY sponge-camo finish—prep, cure tricks, and an urban-modern colorway.

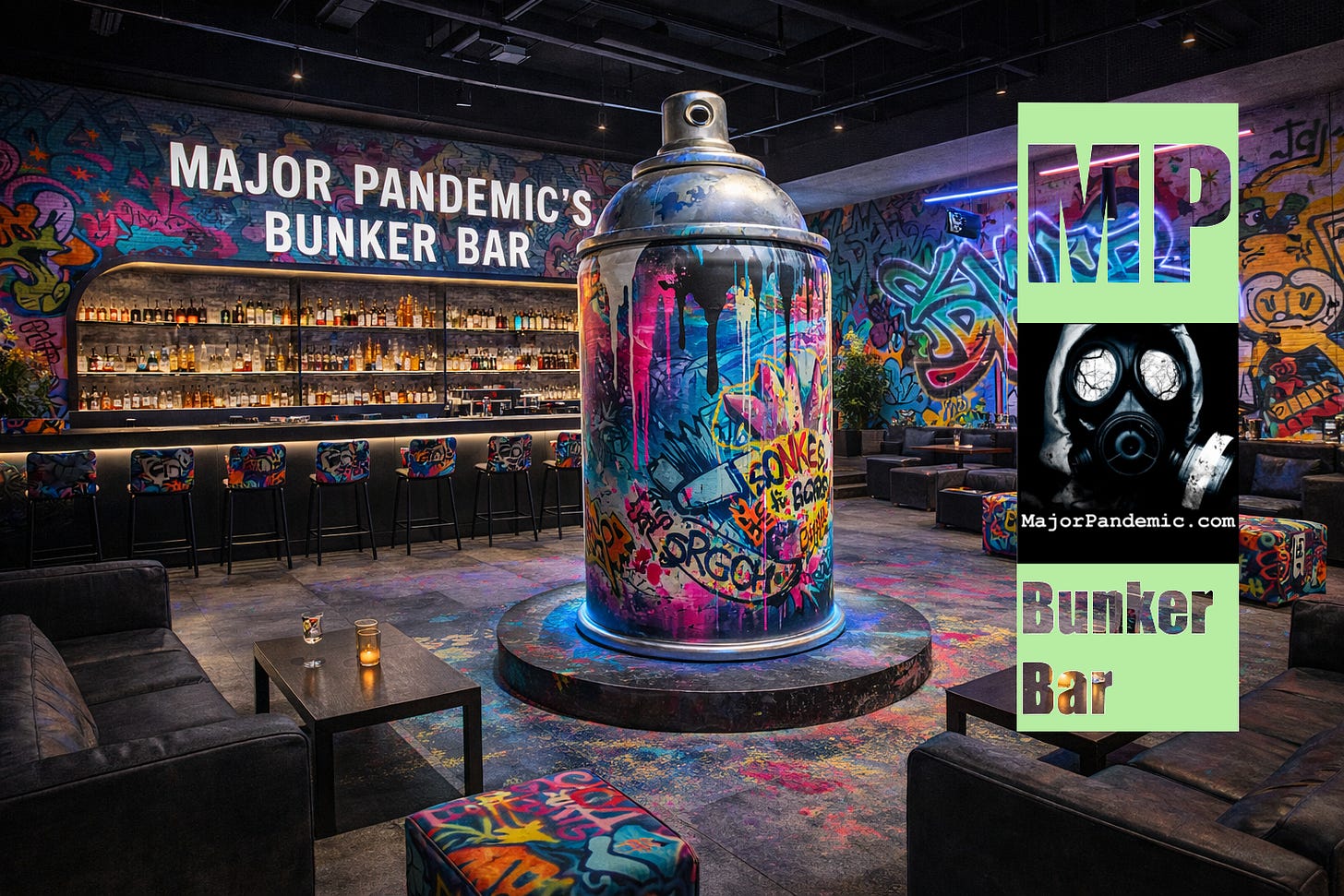

Welcome back to Major Pandemic’s Bunker Bar—managed by Becky Bunker—where every episode is part gear talk, part garage therapy, and part “support the mission” reminder.

This week’s project is a Brownells/PWS short-stroke piston BRN-180 (AR-180 style) that’s been sewing-machine reliable for roughly 6,500–7,000 rounds and earned a refresh instead of retirement. One standout upgrade is a Geissele SSP single-stage trigger—fast reset and built for a “super fast” steel-banger setup out to 300 yards.

The real focus, though, is the finish: a DIY camo job using Brownells Alumahyde, an epoxy-style spray that can deliver near–Cerakote toughness if you’re patient and do the process right. The biggest secret isn’t magic paint—it’s adhesion. On anodized aluminum especially, surface prep and timing matter. A quick tack-dry window between colors helps layers bond and reduces peeling later.

The method starts with two rules: function-test the gun before you paint anything, and don’t spray an assembled rifle. Break it down to parts, degrease aggressively (brake cleaner or acetone), and hang everything so you’re not flipping parts and ruining fresh coats. A quick torch wave or heat-gun pass can help drive off surface moisture before paint goes on.

From there, Alumahyde is simple but finicky. Shake constantly, expect occasional clogs, and keep spare nozzles on hand. Between coats, invert the can and spray until only air comes out—this clears the nozzle and helps the can stay usable.

For colors, the core palette leans urban-modern: Parkerized Gray as the base, with black and silver as companions. The camo is applied with a sponge method—cut foam into shapes, dab a few blotches per color, and stop before you overwork it. The featured look is Parkerized Gray with big black blotches and quick silver accents, dotted and smudged for depth. It’s designed to pop once black accessories and the optic go back on—and it can save serious money versus sending parts out for professional Cerakote.

To speed curing, the finish gets a gentle bake: about 150°F for 8–10 hours. It’s a practical balance—enough heat to harden the coating while staying in a safer zone for many polymer parts.

For more BRN-180 updates, DIY finishing tricks, and bunker-bar build talk, follow along at MajorPandemic.com.